Contents

SHIMANO INC.

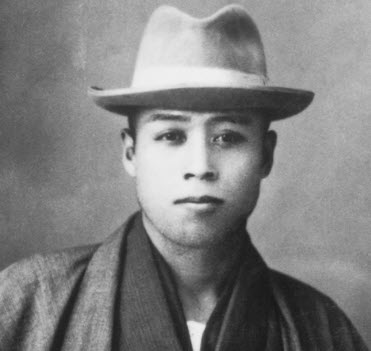

Shimano dates back to 1921, when Shozaburo Shimano founded Shimano Iron Works in Higashi Minato in Sakai City when he was 26 years old. In fact, on the site of a demolished celluloid factory, he rented a nearly 40-square-meter area. The monthly rent was 5 yen. At that time, the new establishment had only a single lathe, measuring about 1.8 meters long. He had borrowed that machine from Sano Iron Works, benefiting from his friendship with its owner.

SHOZABURO TAKES A DIFFERENT PATH

The town was a legendary blacksmithing center known for its swords and gun barrels. However, rather than follow his father into farming, Shozaburo had apprenticed at an iron works after high school. However, by the time he founded his own business, Shozaburo had already decided to produce free wheels. As a result, in ten years Shimano was exporting these freewheels to China.

for its swords and gun barrels. However, rather than follow his father into farming, Shozaburo had apprenticed at an iron works after high school. However, by the time he founded his own business, Shozaburo had already decided to produce free wheels. As a result, in ten years Shimano was exporting these freewheels to China.

From 1930 to 1936 Shimano produce 30,000 single-speed freewheels. Important to note, to establish reputation for quality they gave two free replacements if a product failed. In fact, by the mid 30’s they employ 130 employees working 30 machines in a 13,000 square metre factory.

Unfortunately, around 1937, they were forced to reduce freewheel production when the government forces them to manufacture artillery shell fuses for the Japanese navy.

Consequently, the business was incorporated as a limited corporation in January 1940 under the name Shimano Iron Works Co., Ltd. In 1951, it was renamed Shimano Industrial Co., Ltd.

SHIMANO SPEED CHANGER DERAILLEURS

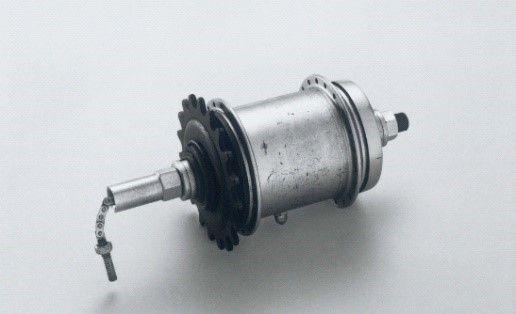

In fact, in 1956 Shimano began making its famous derailleurs in. Also called external speed changers, these were the mechanisms that moved the bicycle chain from gear to gear on ten-speed bikes and the like. To note, the next year the company began producing an internal, three-speed gearing mechanism that was enclosed in the hub of the rear wheel.

This internal speed changer was introduced to the U.S. market a few years later and soon became the standard for three-speed bikes. Furthermore, in 1960 Shimano installed a cold forge that enabled stronger products to be made in a more efficient fashion.

Shozaburo Shimano eventually turned over management of the business to his three sons. Surprisingly, even though the company made brakes and other components, Shimano refused to produce complete bicycles. “Our founder said, ‘never ever compete with a customer,'” remarked one of Shimano’s sons to the Straits Times. Shozburo passes away in 1958 and his son, Shozo becomes president.

SHIMANO SERVICE CENTERS APPEAR

In 1960, Shimano Service Centers are opened in five cities in Japan: Fukuoka; Hiroshima; Okayama; Osaka; and Sapporo on the back of hub gear success. Eventually, In 1965 Shimano American Corporation was established in New York. Interesting to note, as the continued existence of Shimano in the USA market seemed to be assured the company established Shimano American Corporation with office in New York City with Yoshizo Shimano as the president.

The sixties were very creative for Shimano as they started manufacturing the following components:

One: The five-speed ‘Archery’ derailleur

Two: 5 speeds, and first Shimano-branded, derailleur introduced.

Three: Bi-matic, two speed hub gear with coaster brake.

Four: Automatic Five, a five-speed derailleur that auto- Five: shifted using centrifugal wheel forces.

Shimano begins cold forging products.

Six:Hydraulic disc brake with linked front and rear calipers.

COMPANY BUILDS THE LARGEST BICYCLE PLANT

In 1970, Shimano built what was then the largest bicycle plant, located in Yamaguchi Prefecture, Japan. Later in the decade, according to Design Week, Shimano began hiring engineers to create a unified look among component systems as well as elevating their performance. Consequently, a European unit, Shimano (Europa) GmbH, was established in Düsseldorf in 1972 with just two employees. Fortunately, the company’s shares began trading on the Osaka Securities Exchange the same year and were also listed on the Tokyo Stock Exchange in 1973.

Shimano’s first manufacturing plant abroad was set up in 1973 in Singapore. Opening a sales office in California in 1974, the company was well placed to ride the booming bike market in the United States during the 1970s.

In 1978, Dura Ace EX 7200 is released:

Ahead of the Pack in the 1980s

Shimano continued to refine its biking products, creating new market leaders. The AX line of components for bicycle racing came out in 1980, followed two years later by a series for mountain bikes dubbed Deore XT.

Dura Ace 7300 AX group 1980 |  1st generation Deore |

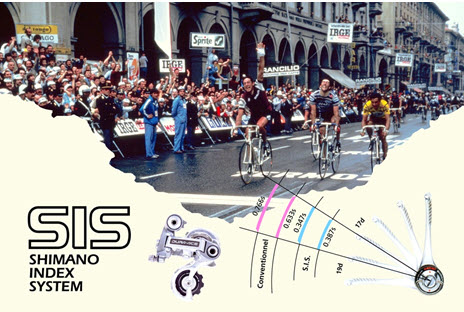

The Shimano Index System allowed cyclists to dial in to specific gears by numbers. Annual sales exceeded ¥50 billion in the mid-1980s. Of course, at this time Shimano employed 1,500 people around the world.

Shimano Dura-Ace 7400 Index System Groupset 1984 Shimano Dura-Ace 7400 Index System Groupset 1984 |

Shimano beat its European competitors to the mountain biking craze, observed the Far East Economic Review. The company developed a thumb-shifting mechanism specifically for mountain bikes and produced tougher versions of its brakes and steering controls to stand up to knobby tire abuse. In fact, by the late 1980s Shimano was considered the standard for mountain bike components.

The range of Shimano’s cycling offerings expanded throughout the 1980s. New shifting systems continued to be developed, such as the Rapidfire Remote (1989) for mountain bikes. The company began selling a line of bike shoes in 1988.

SHIMANO SUBSIDIARY ESTABLISHED

Shimano set up a UK subsidiary that focused on fishing tackle sales in 1988. In the same year, Shimano shifted some of its fishing reel production to Singapore. However, due to the rise of the yen, Shimao was producing about ¥4 billion ($26 million) worth of bike parts a year. As a result, Shimano established three subsidiaries in the Netherlands that sold an array of products.

1988 Andy Hampsten (Seven-Eleven Team) wins the Giro d’Italia with DURA-ACE.

Sales were ¥84 billion in 1989. Exports of Japanese bicycles and components as a whole grew furiously in the late 1980s, reported the Asahi News Service, reaching ¥115.4 billion ($848.7 million) in 1990. By now, one-third of Shimano’s production went to Europe.

Sales were ¥84 billion in 1989. Exports of Japanese bicycles and components as a whole grew furiously in the late 1980s, reported the Asahi News Service, reaching ¥115.4 billion ($848.7 million) in 1990. By now, one-third of Shimano’s production went to Europe.

Global Expansion Continues in the 1990s

Shimano opened a plant in Malaysia in 1990. In the same year, the company bought an interest in Alfred Thun S.p.A. This was renamed Shimano Italia S.p.A. after the rest of the stock was acquired. Eventually, a fishing equipment unit was also set up in Italy in 1990. In addition, Shimano was expanding its Singapore operations. Additionally, the company also set up subsidiaries in Belgium and Indonesia in the early 1990s. The parent company’s name was changed to Shimano, Inc. in 1991.

The proprietary SPD (Shimano Pedaling Dynamics) line of quick-release “clipless” pedals called was introduced in 1990. Furthermore, a line of Shoes and Pedals designed to be ideal for both pedaling efficiency and for walking.

DURA-ACE (7400 series) with Dual Control Lever is released. The dual-control lever incorporates a shifter mechanism into the brake lever. As a result, this made it possible to change speeds without removing one’s hands from handlebars.

In 1995, Shimano rolled out its Nexus line of seven- and four-speed internal hubs for cruiser bicycles, which were growing in popularity in the United States due to their retro styling and simplicity of operation. Additionally, Shimano was also developing an in-hub gear system that could be locked to prevent theft. Finally, it was introduced to the Japanese market in 1997.

COMPETITION HEATS UP IN ASIA

Competition in Asia increased towards the end of the decade as European manufacturers entered this market. Bicycles had long been a staple form of transportation in China, and, as its economy grew, so did the demand for high-end bikes. Amazingly, the Far Eastern Economic Review had observed that most of China’s 320 million bicycles did not have gears in the early 1990s. However, this was changing rapidly, and Shimano claimed a 50 percent market share on gears there.

Unfortunately, after reports of cyclists being injured by broken cranks, Shimano recalled more than 2.5 million of them in 1997. As a result, this became the largest recall in the bike industry to date. It was reported the Los Angeles Times, and cost the company $15 million or more. Due to the popularity of Shimano’s mountain bikes, the affected parts had been installed in about 50 different brands over the previous three years.

2000 and Beyond

Shimano became more visible than ever on the global stage as longtime user Lance Armstrong began his winning streak at the Tour de France in 1999. While overseas production accounted for 30 percent of production in 2000, exports accounted for more than 80 percent of revenues of ¥141 billion. Unfortunately, as the Japanese bike market stalled the Nikkei Weekly reported Shimano was shifting the focus of its overseas plants to supplying local bike manufacturers rather than producing parts to export back to Japan. Shimano was investing ¥1 billion to boost production at its Shanghai plant by 60 percent and was adding a three-speed gear line there to meet new demand.

SHIMANO BILLION DOLLAR FACTORY

In 2001, the company set up a ¥5 billion factory in the Czech Republic to meet booming bike demand in Eastern Europe, as well as building a plant in mainland China. A Taiwanese unit was established in 2002, and a second, ¥2 billion ($17 million) factory opened in the People’s Republic of China in 2003. Shimano also opened a ¥500 million ($4 million) fishing rod production facility on the site of its Kunshan, China, bike parts complex. The company was aiming to increase overseas production to half of total production by 2004, reported Asia Pulse.

AUTOMATIC GEAR SHIFTING

After extensive design and testing, an automatic gear shifter for bicycles was announced in late 2003. The device used magnets and other sensors to determine a bike’s speed and make shift adjustments accordingly. Shimano was hoping to sell 50,000 units a year at ¥200,000 ($1800) each. Yoshizo Shimano told the Financial Times that the motivation for the idea was to allow bike commuters to concentrate on traffic by freeing them from the distraction of selecting gears.

CHRONOLOGICAL EVENTS FROM 1991

1991

Corporate name is changed from Shimano Industrial Works to SHIMANO INC.

Consequently, the XTR series of mountain bike racing components is in the market. The first line of mountain bike components for professional racers.

1992

Keizo Shimano becomes third president.

The cycle center (Bicycle Museum) opens. With the cooperation of Sakai city where Shimano Inc. is located, it is established on the area next to Daisen Park.

1995

Yoshizo Shimano becomes fourth president.

1996

DURA-ACE 7700 is in the market. 7700 series are developed after thorough review of the previous derailleur system based on the philosophy of “Stress-Free”.

1998

Interestingly to note, this series is a special Dura-Ace released in commemoration of 25 year since its introduction in to the market.

1999

Lance Armstrong of the US Postal Team won the Tour de France 1999 using Dura-Ace 7700 groupset. However, the U.S. Anti-Doping Agency (USADA) stripped his all seven Tour de France titles in 2012.

2001

Yozo Shimano, Shozo’s son, becomes fifth president.

Shimano (Shanghai) Bicycle Components Co., Shimano Czech Republic s.r.o. and Shimano France Composants Cycles S.A.S. are established.

2004

DURA-ACE 7800 series is in the market. The DURA-ACE 7800 series components are developed with “For 100% Power Transmission Efficiency” as a catchword. This series consisted of 10-speed rear drive trains, HOLLOTECH Ⅱ cranksets, ergonomic dual control levers, and other higher performance components.

SHIMANO ACQUIRES PEARL IZUMI

2008

The brand Pearl Izumi is acquired.

DURA-ACE 7900 series is released. The 7900 series components were developed under the concept of “Evolution of Perfection”. A derailleur comprising these components embedded the shift cable completely. Its crankset consisted of a HOLLOWGRIDE (hollow gear) in addition to a HOLLOWTECH Ⅱ. All other components were also reviewed for optimal design.

2009

2009

Electronic Shifting System DURA-ACE 7970 is in the market. A new technology called “Digital Integrated Intelligence (or Di2 for short) was introduced into DURA-ACE. The DURA-ACE 7900 series equipped with this electronic shifting system provide racers with a “complete stress-free” function.

2010

Shimano STEPS ,the first components for power-assisted bicycles, is released.

2012

DURA-ACE 9000 series is released. The DURA-ACE 9000 series have been fully re-engineered across every system. Highlights include a robust four-arm cranksets, the new SLR-EV brake system and a new 11-speed drive train.

2014

XTR M9000, M9020 and M9050 (Di2) series is released.

Shimano Italy Bicycle Components S.r.l. is established.

2016

The DURA-ACE R9100 series (road racing components) equipped with power meter are released.

We earn from qualified Amazon purchases with NO cost to you. In fact, ANY item that you need or were going to purchased anyway through the links above, helps support this site. Thank you for your support!