Competitive Cyclist Sale

Competitive Cyclist Sale

The Airline: Bicycle Tubing Transformed

Breaking New Ground in Steel Frame Design

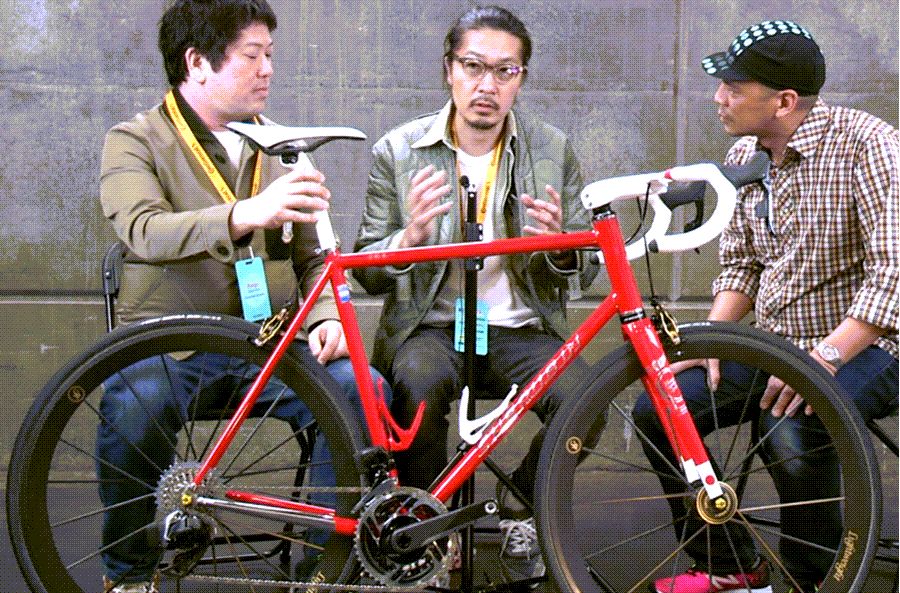

The Cherubim Airline with innovative bicycle tubing is this weeks “Japanese Bicycle of the Week”. When Cherubim unveiled their latest frame building masterpiece, the Airline, they revolutionized steel fabrication techniques. Specifically, this breakthrough in bicycle tubing manipulation showcases how traditional steel can transcend basic frame geometry. Moreover, the Airline’s sophisticated tube shaping demonstrates unprecedented metal forming capabilities.

this weeks “Japanese Bicycle of the Week”. When Cherubim unveiled their latest frame building masterpiece, the Airline, they revolutionized steel fabrication techniques. Specifically, this breakthrough in bicycle tubing manipulation showcases how traditional steel can transcend basic frame geometry. Moreover, the Airline’s sophisticated tube shaping demonstrates unprecedented metal forming capabilities.

As a result, each precisely crafted curve transforms standard steel alloy into architectural art. Furthermore, the innovative frame construction challenges conventional building methods. Subsequently, this progression in tube forming technology opens new possibilities for steel frame design.

Modern Integration Meets Traditional Craftsmanship

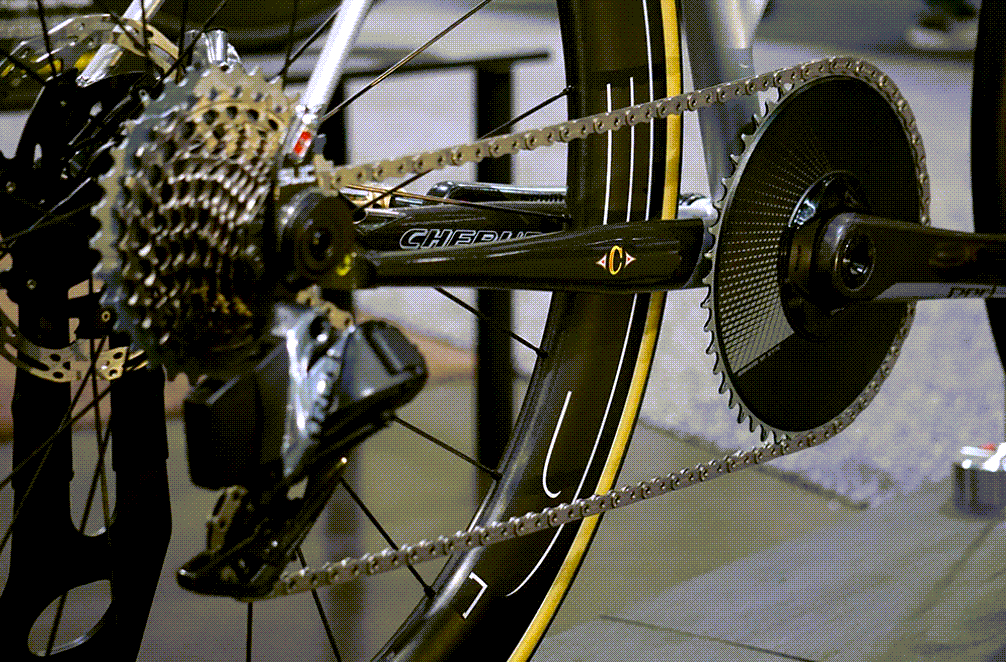

The Airline seamlessly merges classic steel craftsmanship with contemporary components. In particular, the frame geometry perfectly complements the new ENVE aero carbon stem and Zipp aero handlebars. Subsequently, the design harmonizes with SRAM’s cutting-edge 1×12 Red AXS group.

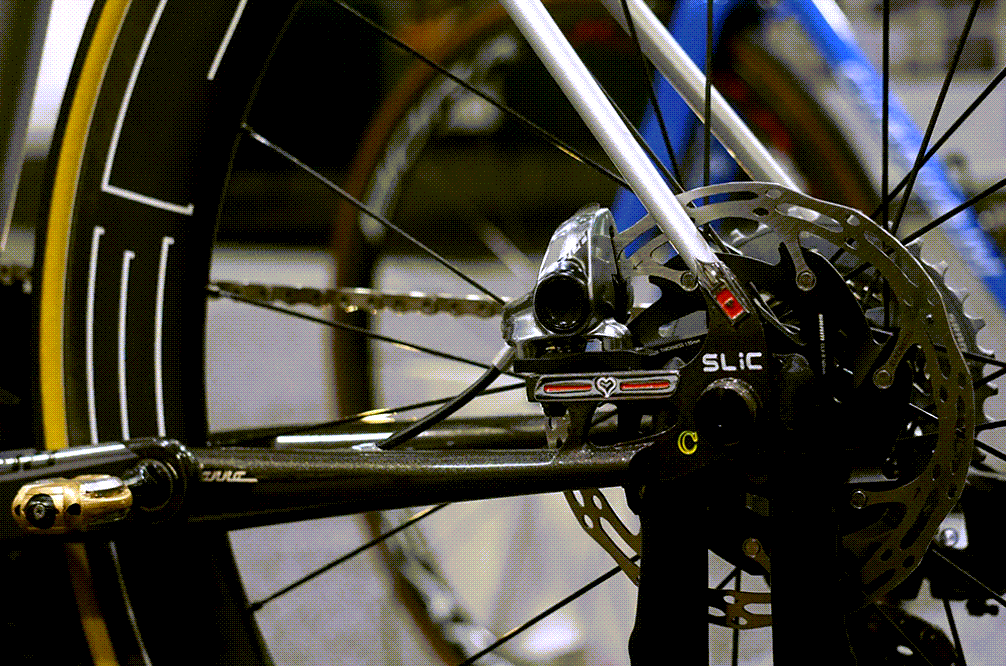

Meanwhile, the most remarkable tube manipulation appears in the flat mount brake design. Rather than using conventional spacers, Cherubim developed a dedicated shelf through careful steel fabrication. Consequently, this solution enhances both structural integrity and aesthetic appeal.

Furthermore, the integration of modern components with traditional steel construction demonstrates the versatility of properly manipulated frame tubing. Therefore, the Airline proves that steel remains relevant in an era of carbon fiber dominance.

Revolutionary Tubing Development

The essence of the Airline’s innovation lies in its advanced butted tubing technique. Specifically, Cherubim mastered custom bicycle tubing through meticulous hand-filing processes. Starting with a 46mm diameter steel alloy tube of 1mm thickness, their frame building expertise enabled precise shaping to achieve varying wall thicknesses of 0.8mm, 0.5mm, and 0.8mm.

Furthermore, this metal forming process allows for exact control over frame stiffness. Therefore, each section of tubing contributes to the bike’s overall performance characteristics.

The technical process involves several critical steps. Initially, the team selects premium steel alloy tubes based on specific strength-to-weight ratios. Subsequently, they employ a combination of cold working and precise heat treatment to maintain structural integrity during manipulation.

Moreover, the filing process requires exceptional skill, as removing just 0.1mm too much material could compromise the tube’s performance. The team uses specialized measuring tools accurate to 0.01mm to ensure consistency throughout the tubing walls.

Engineering Meets Experimentation

Cherubim’s dedication to frame construction excellence extends beyond aesthetics. In particular, they engineered an innovative dropout design for thru-axles and flat mount brakes. This sophisticated steel fabrication prevents excessive chainstay rigidity, a common challenge in modern frame geometry.

Moreover, the team explored the relationship between a highly rigid top tube and an intentionally compliant down tube. As a result, this unique approach to tube manipulation creates distinctive riding dynamics.

The engineering process involves extensive finite element analysis (FEA) to predict stress distribution throughout the frame.

Subsequently, each tube’s diameter and wall thickness is optimized for its specific location and purpose. Furthermore, the team develops custom tooling for each unique tube shape, ensuring repeatable results in future productions.

The Philosophy Behind the Innovation

For Cherubim, experimental frame building serves multiple purposes. Initially, these projects facilitate testing new metal forming techniques without compromising customer builds. Furthermore, this hands-on exploration of bicycle tubing and frame design yields deeper insights than theoretical knowledge alone.

Subsequently, successful steel fabrication innovations transfer to regular custom bikes. Therefore, each show bike advances their frame building expertise. The team’s approach to bicycle tubing development combines traditional craftsmanship with modern engineering principles.

Specifically, they maintain detailed documentation of each experimental process, including metallurgical analysis of how different forming techniques affect the steel’s grain structure. Moreover, this scientific approach to traditional craft enables consistent reproduction of successful techniques.

Technical Innovations in Tube Formation

The butted tubing process represents just one aspect of Cherubim’s technical innovation. Their proprietary tube forming method involves carefully controlled heating cycles that prevent material fatigue. Subsequently, each tube undergoes multiple quality control checks, including ultrasonic testing to verify wall thickness consistency. Furthermore, the team employs specialized jigs and fixtures to maintain precise alignment during the forming process.

The technical specifications of their tube manipulation process are impressive. Temperature control during forming must remain within a 5-degree Celsius window to maintain optimal material properties. Meanwhile, the filing process requires up to six hours per tube to achieve the desired wall thickness variations. Consequently, each frame represents over 100 hours of skilled labor in tube preparation alone.

Learning Through Building

The Airline project has already yielded valuable insights in tube shaping. Notably, both the innovative dropout design and external butted tubing techniques have proven production-ready. Moreover, this approach to bicycle tubing development illustrates how traditional steel alloys can adapt to modern standards.

As the team continues testing in Japan, they’ll gather more data about the frame’s unique characteristics. Consequently, future Cherubim frame geometry will benefit from these experiments.

In conclusion, the Cherubim Airline represents more than innovative bicycle tubing techniques. Rather, it demonstrates how dedicated frame building can push the boundaries of steel fabrication.

Through careful tube manipulation and bold frame geometry choices, Cherubim has created a bike that honors traditional steel craftsmanship while embracing modern technology. As a result, the Airline serves as both a showcase of current capabilities and a preview of future innovations in metal forming.

We earn from qualified Amazon purchases with NO cost to you. ANY item that you need or were going to purchased anyway through any of our links, helps support this site. Thank you for your support!

If you enjoyed learning about this week’s featured bicycle, don’t miss out on some cycling information you can use and enjoy! Visit our website at pacelinebikes.com Plus, check out our YouTube channel, Bicycle Restoration Man, for detailed restoration videos and showcases of our finished projects. Subscribe and join our community of bike enthusiasts!